Tel: +39 (0) 35 925032

Email: commerciale@unigasket.it

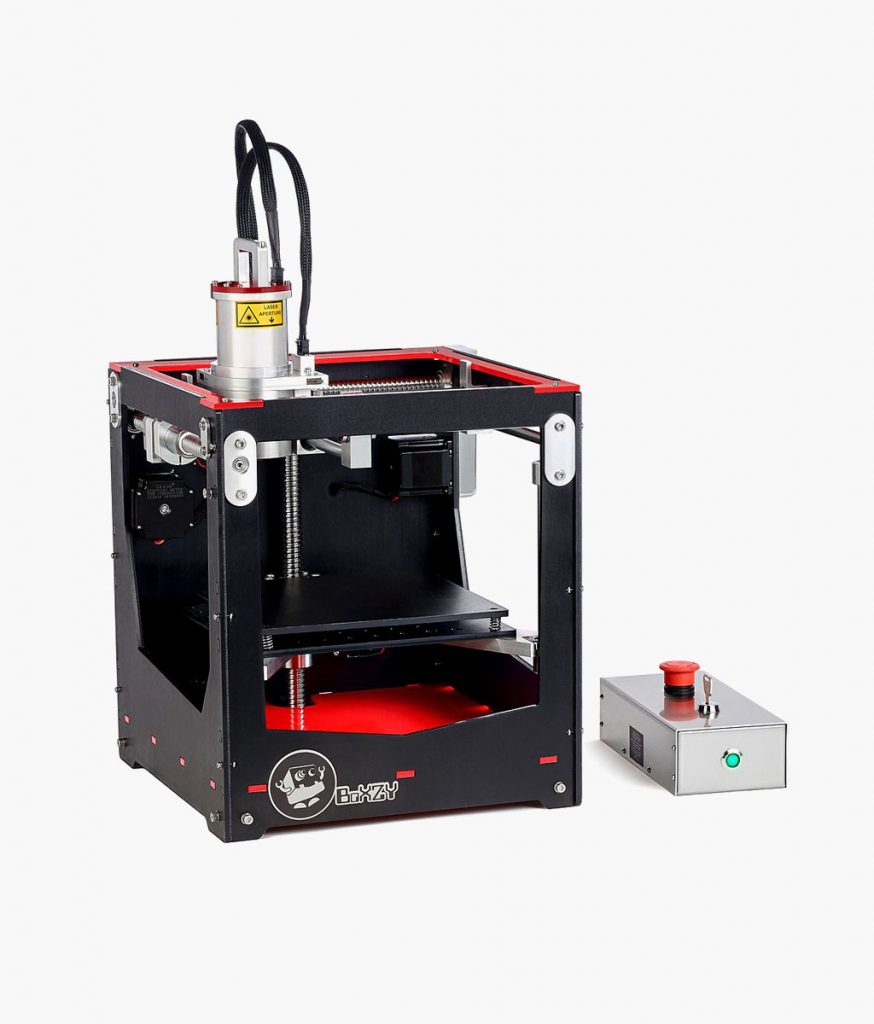

Injection molding machine

- Unigasket

- Injection molding machine

Injection molding machine

The 27 billion pounds of plastics produced in this country in the mid1970’s found use in every major market in the U.S. Automobiles, boats,construction, packaging, electrical / electronics, pipe and fittingsand consumer goods.

Today, more than ever, injection molded productsare found everywhere. The success of Injection Molding processing lies in the precise control of material component flow at high pressures.

Unigasket hoses have the ability to withstand continuous high pressures and temperatures, easily accommodate the numerous tight bends of the installation, have low volumetric expansion and are superior to clean.

| Category | Coating |

|---|---|

| Applications | Industrial |

Description

Contacts

Description

Temperature

From -70°C to 260°C

Specifications

| Category | Coating |

|---|---|

| Advantages | Superior resistance to urethane monomers and abrasive fillers |

| Non-stick and cleanable | |

| Higher operating temperature range versus rubber hydraulic hoses | |

| Easily withstands the 400°F hot oil media | |

| Greater hose flexibility | |

| Easier to handle | |

| Minimum downtime by preventing material build-up | |

| No contamination of critical materials | |

| High productivity and reliability | |

| Greater safety and operating efficiency | |

| Less maintenance costLonger service life |

Contacts